Waterway Pressure Side Pool Cleaner Booster Pump | 3810430-1PDA

Waterway Pressure Side Pool Cleaner Booster Pump | 3810430-1PDA

SKU#: 3810430-1PDA

3810430-1PDA Waterway Pressure Side Pool Cleaner Booster Pump for Pentair , Polaris and Hayward Pressure Side Pool Cleaners

Booster Pump 3/4 HP 60 HZ 48 Frame 115/230V with Union and Hose Kit

- Suitable for all swimming pool pressure cleaners.

- Best replacement for any 3/4 HP booster pump.

- Comes with a tall, versatile mounting base.

- Equipped with high performance square flange 3/4 HP, 115/230V motor. Provides extra quiet, long life operation & optimum energy efficiency.

- Maintains one of the highest head pressures in the industry.

- Comes with everything you need to install or retrofit the pump: soft tube connector, pump quick connect retainer, and six feet of reinforced flexible pump hose.

-

Product Details

About this product

Description

Electrical The starting current of the booster pump motor may exceed 15 amps. It is recommended that a 20 amp service breaker be used for the pump. The booster pump motor is factory wired for 240 volts, but can be wired for either 120 or 240 volts. To rewire to 120 volt, follow the instructions on the name plate located on the back of the motor or the sizing plate on the side of the motor. A separate time clock (in addition to the filtration system time clock) is recommended to control the On/Off functions of the booster pump. A manual switch can also be used. If a time clock is used, set it to turn the pump on half an hour after the pool filtration pump is turned on, and turn the pump off at least half an hour before the filtration pump shuts off. Periodically check the time clock settings to make sure they are properly synchronized.

Highlights

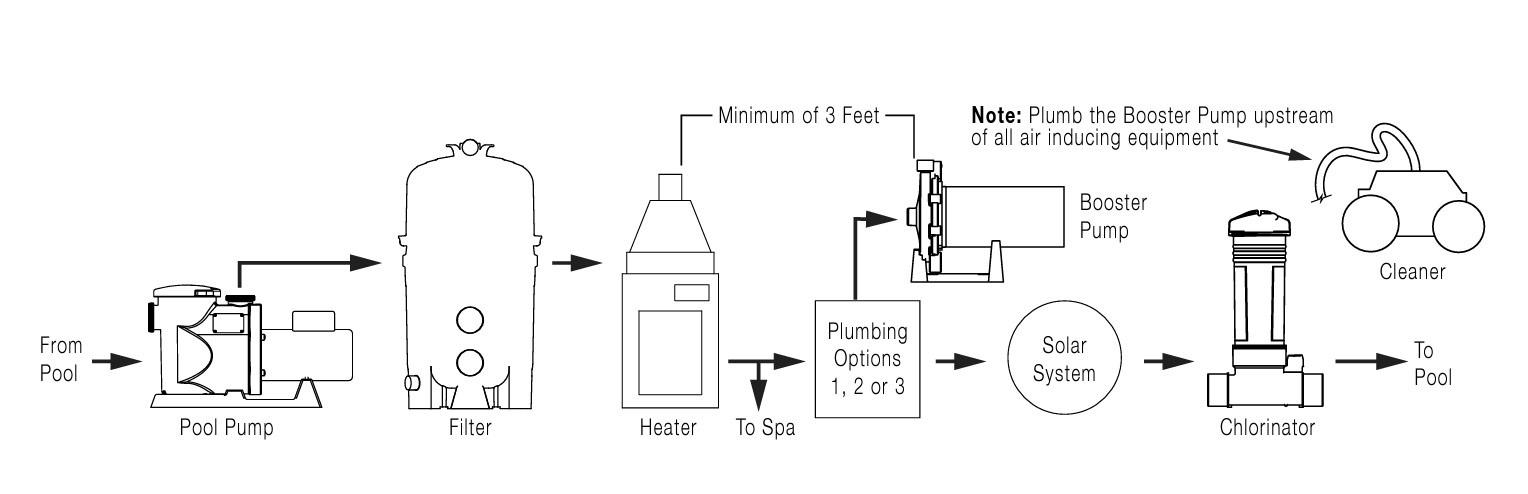

The Waterway Booster Pump requires a dedicated return line. Plumb the booster pump into the system so that it always receives flow from the f iltration pump. To ensure proper function of the pump and the cleaner, refer to the Typical Installation diagram and adhere to the following guidelines for specific equipment.

- Plumb the dedicated line upstream of all air inducing equipment.

- If a heater is installed on the system, tap the inlet for the booster pump into the return line downstream and at least three feet from the heater discharge. Do not tap the booster pump inlet into the three-foot section of heat sink pipe that comes directly out of the heater.

- Some solar heating systems utilize the entire water flow when the panels are being purged of air. If the pump is installed in a non-flow pipe during solar panel purges, install an automatic override to shut off the pump.

- Plumb the booster pump inlet higher, upstream and as far away as possible from the chlorinator.

Features

- Suitable for all swimming pool pressure cleaners.

- Best replacement for any 3/4 HP booster pump.

- Comes with a tall, versatile mounting base.

- Equipped with high performance square flange 3/4 HP, 115/230V motor. Provides extra quiet, long life operation & optimum energy efficiency.

- Maintains one of the highest head pressures in the industry.

- Comes with everything you need to install or retrofit the pump: soft tube connector, pump quick connect retainer, and six feet of reinforced flexible pump hose.

Brand Information

Waterway Plastics is proud to design, engineer and produce our quality line of products right here in the USA, using only premium NSF Approved materials & meeting all Certifications and Standards, at our 460,000 sq. ft. facility in Oxnard, CA. Waterway has been committed to innovation & excellence since 1973.

Visit Manufacturers Website -

Specifications

To ensure proper water flow:

To ensure proper water flow:- Use rigid PVC pipe with a minimum diameter of 3/4”, (1-1/2” is recommended) for the dedicated return line. Flexible PVC piping is not recommended as it can be damaged by expansion and movement caused by the surge of pump pressure.

- The booster pump inlet connection line should be at least 3/4” pipe. The supplied 3/4” barb fitting is designed to work with the Waterway supplied reinforced hose.

- Do not tap into the top of a horizontal line.

Installing the Pump

1. Mount the pump using two concrete expansion anchors to ensure stability.

2. Install supplied 3/4” barb fitting onto pump discharge and supply ports using Teflon® tape as sealant.

3. Measure and cut reinforced hose ensuring cut is clean, with no more than a 30º off straight edge.

4. Push the hose onto the hose barbed fitting until it is flush against the hose barb base. Secure the hose with supplied hose clamps. -

Q/A

No Questions

Log in

Create a Free Account

Please fill out sign-up form

Sign up with your social media account

Or

Fill out sign up form

Why create an account

Sign up with your social media account