Jandy® Igniter Assembly for Hi-E2® Heater | R0016400

Jandy® Igniter Assembly for Hi-E2® Heater | R0016400

SKU#: R0016400

Jandy® Igniter Assembly for Hi-E2® 200-400 BTU Heaters

- Compatible with Jandy Laars HI-E Heaters (Years 1991-1996)

- Compatible with Jandy Laars HI-E2 Heaters (Years 1997-Current)

Write a Review

Jandy® Igniter Assembly for Hi-E2® Heater | R0016400

SKU# R0016400

Manufacturer: Jandy

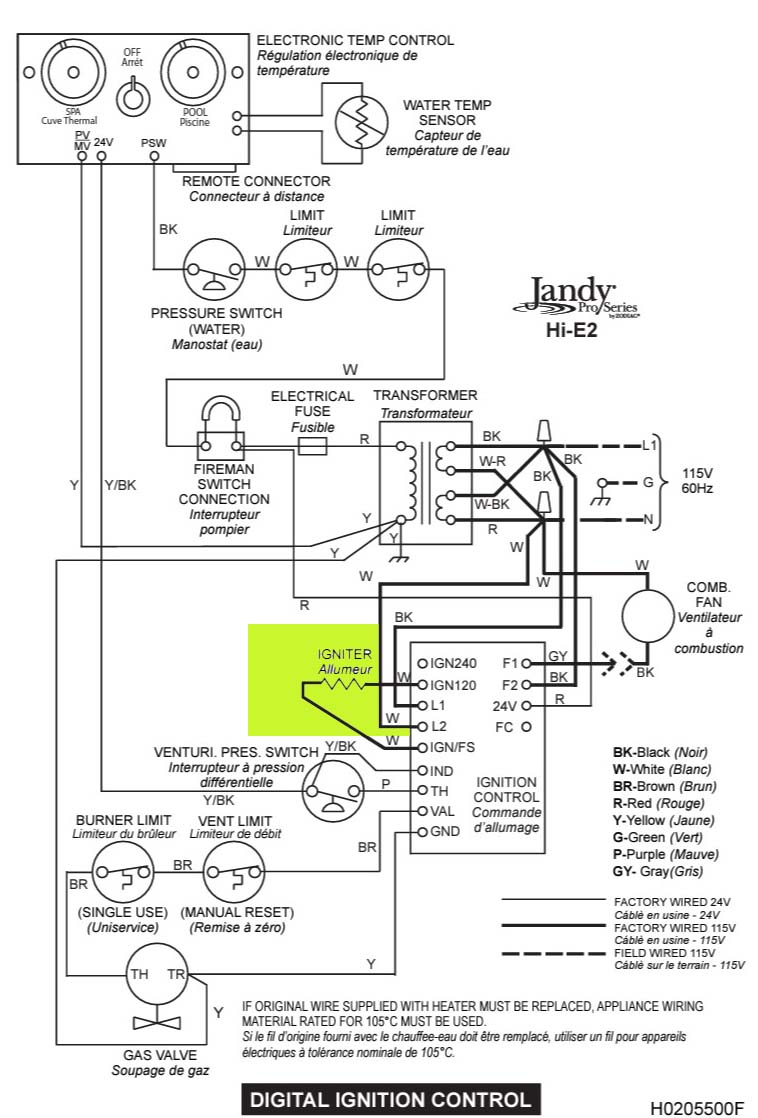

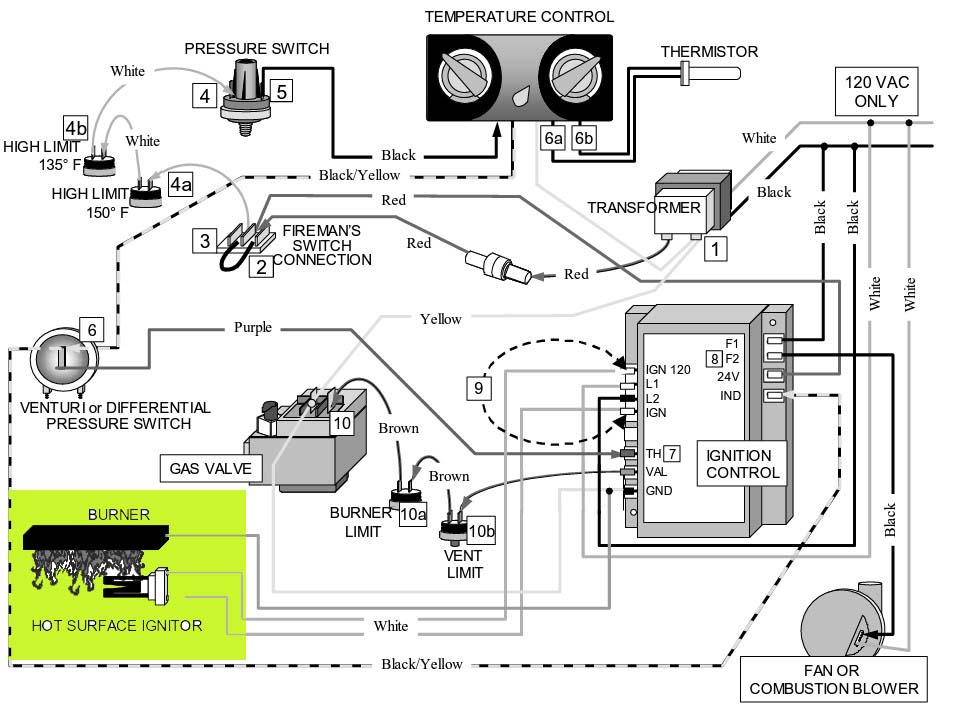

Igniter - The hot surface igniter is a ceramic element which becomes very hot when electrical power is applied to it. It functions both as an igniter and as flame sensor. As a sensor, it is the electrode through which the ignition control detects “rectification” of current passed through the flame. Inadequate rectification indicates an unsatisfactory flame condition. The ignition control responds to the flame signal provided by the ignitor.

Igniter

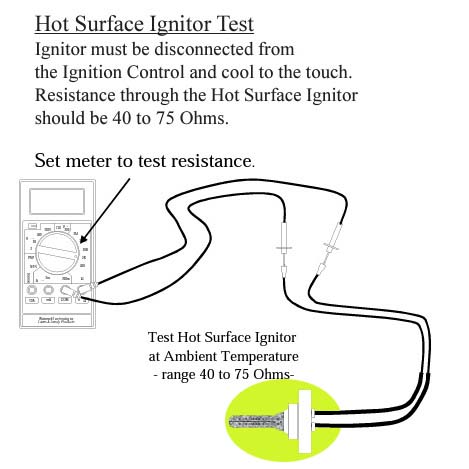

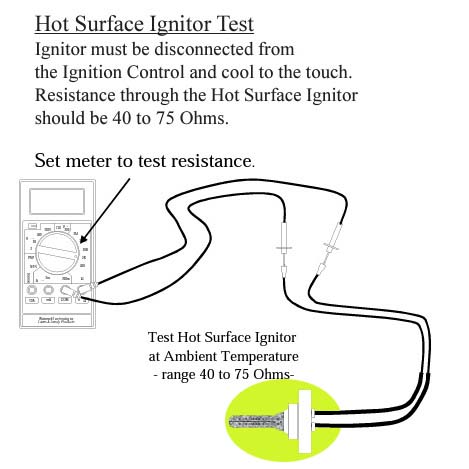

The igniter should glow during ignition attempts as outlined in the earlier section on ignition control. If it does not, connect the voltmeter between terminals marked D and E on the ignition control. If 115V is present during the igniteron portion of the ignition sequence but there is no glow, the igniter is probably defective. If voltage is not found, the ignition control is defective and should be replaced. An igniter which will not glow should be checked by disconnecting the wires from the ignition control and measuring the igniter resistance. A cold igniter should have resistance in the range of 40 to 75 ohms. Replace the igniter if resistance is outside of this range.

-

Product Details

About this product

Description

Ignition Control - The ignition control provides energy for ignition of the air/gas mixture, monitors the flame and controls the combustion blower and gas valve. When the temperature control requires heat, the ignition control starts the blower, providing a pre-purge of the combustion chamber. Then it applies electrical power to a “hot surface” igniter. When the igniter is hot enough, it opens the gas valve. It has sophisticated means to sense ignition and flame condition so that unburned gas will not escape. After the burner is shut off, it continues blower operation to provide a post-purge period.

Highlights

Mini Igniter

Mini Igniter OEM Jandy Pat

OEM Jandy Pat Fits Zodiac Jandy Hi-E2® Heater Models

Fits Zodiac Jandy Hi-E2® Heater ModelsFeatures

Igniter - The hot surface igniter is a ceramic element which becomes very hot when electrical power is applied to it. It functions both as an igniter and as flame sensor. As a sensor, it is the electrode through which the ignition control detects “rectification” of current passed through the flame. Inadequate rectification indicates an unsatisfactory flame condition. The ignition control responds to the flame signal provided by the ignitor.

Igniter

The igniter should glow during ignition attempts as outlined in the earlier section on ignition control. If it does not, connect the voltmeter between terminals marked D and E on the ignition control. If 115V is present during the igniteron portion of the ignition sequence but there is no glow, the igniter is probably defective. If voltage is not found, the ignition control is defective and should be replaced. An igniter which will not glow should be checked by disconnecting the wires from the ignition control and measuring the igniter resistance. A cold igniter should have resistance in the range of 40 to 75 ohms. Replace the igniter if resistance is outside of this range.

Brand Information

Build the perfect pool environment with Jandy professional-grade swimming pool equipment. With a full line of pumps, filters, heaters, lights, valves, water sanitizers, and the automation solutions to control it all, Jandy has the complete equipment package for any swimming pool or spa.

Visit Manufacturers Website -

Specifications

Ignition Control There will be voltage at point 8, which is the “MVP” terminal of the ignition control, only when there is an attempt to ignite the burner or when the ignition control’s f lame sensing system has determined that it is OK to allow burner operation. Even if voltage has been confirmed at point 7, the “trial for ignition” sequence is imposed by the ignition control. This sequence consists of a 15 second period of pre-purge blower operation, a 40 second period for heatup of the igniter and a 7 second trial for ignition, during which there is voltage at point 8. If satisfactory ignition is not achieved, the igniter is turned off and the blower is operated for a 45 second post-purge. The system may go through this cycle as many as three (3) times, but thereafter it is “locked out” by the ignition control. Additional attempts will be made only if the call for heat is interrupted by turning off electrical power or setting the control to “Off”.To trouble shoot the ignition control, connect the voltmeter probe at point 8 and set the control to call for heat. Observe that the normal sequence takes place by noting blower operation, the glow of the igniter through the combustion chamber sight glass and then voltage at point 8. If the blower does not operate or the igniter doesn’t glow, investigate as outlined in a later sections. If both of these components operate normally but voltage doesn’t appear at point 8 during the trial for ignition, replace the ignition control. If voltage appears at point 8 but there is no ignition, proceed to analysis of other components.

-

Q/A

No Questions

Log in

Create a Free Account

Please fill out sign-up form

Sign up with your social media account

Or

Fill out sign up form

Why create an account

Sign up with your social media account